Shop Premium Dental Burs Online

Eagle Dental Burs offers an extensive collection of professional-grade dental burs designed to meet the demanding requirements of modern dental practice. Our comprehensive online catalog features premium diamond burs, carbide burs, milling burs, and specialized burs such as IPR burs, surgical burs, endo burs, and perio burs, ensuring that dental professionals have access to the highest quality tools for every clinical application.

Shopping for dental burs online provides unprecedented convenience and selection for busy dental practices. Our curated collection includes everything from basic round burs for routine procedures to specialized finishing burs for complex restorative work. Each product in our inventory undergoes rigorous quality control to ensure consistent performance and reliability in clinical settings.

The advantages of purchasing dental burs online extend beyond convenience to include competitive pricing, detailed product specifications, and expert guidance in product selection. Our platform enables practitioners to compare different bur types, read technical specifications, and make informed purchasing decisions based on their specific clinical needs. With fast shipping and reliable customer service, Eagle Dental Burs ensures that your practice maintains optimal inventory levels without interruption.

Our online dental bur collection features products that meet international quality standards, with detailed product descriptions that help practitioners select the most appropriate instruments for their procedures. Whether you need diamond burs for crown preparation, carbide burs for cavity preparation, or specialty burs for specific applications, our online store provides easy access to professional-grade instruments that deliver consistent clinical results.

What Are Dental Burs?

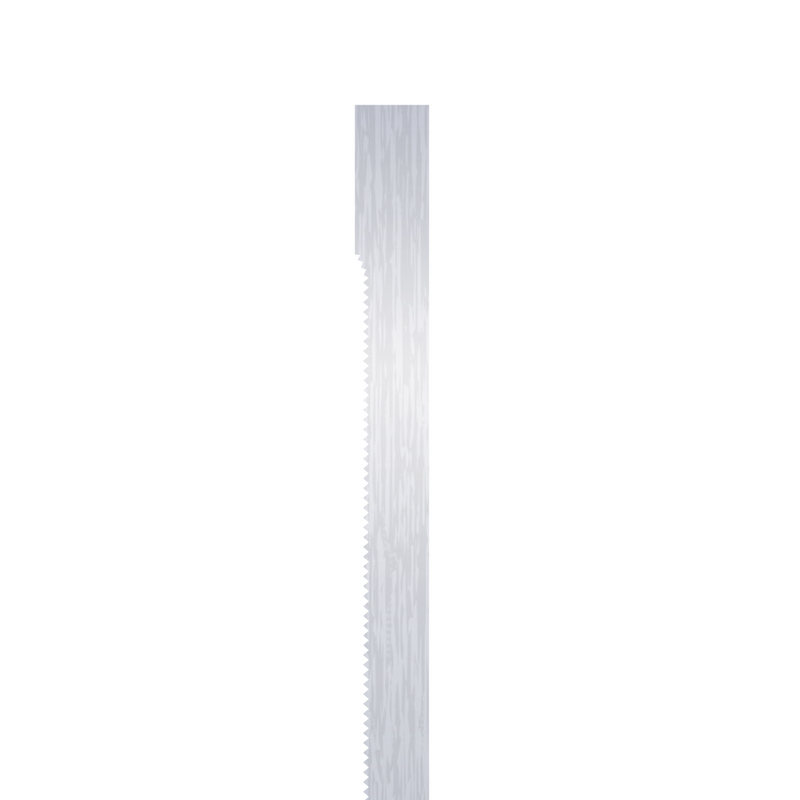

Dental burs are precision-engineered rotary cutting instruments that form the backbone of modern dentistry. These specialized tools are designed to cut, shape, and polish tooth structure and dental materials with exceptional accuracy. The quality and design of dental burs directly impact treatment outcomes, making them one of the most critical instruments in any dental practice.

Dental Burr OR Dental Bur?

Even among professionals, “dental burr” is a common misspelling of the correct term, dental bur. This often happens due to phonetic similarity, but it's important to note that the correct term is always dental burs in clinical settings.

Types of Dental Burs

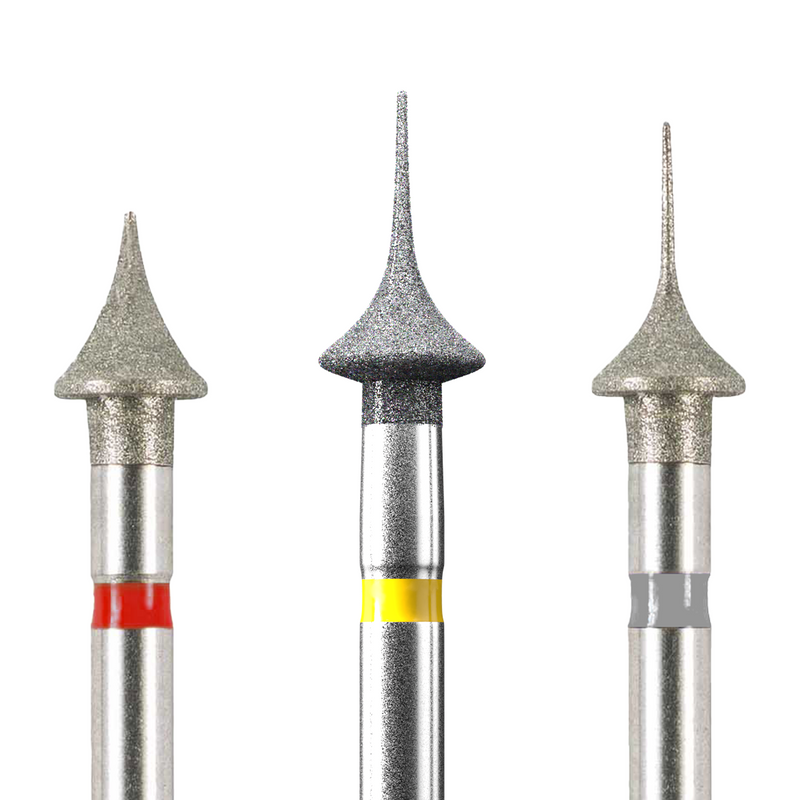

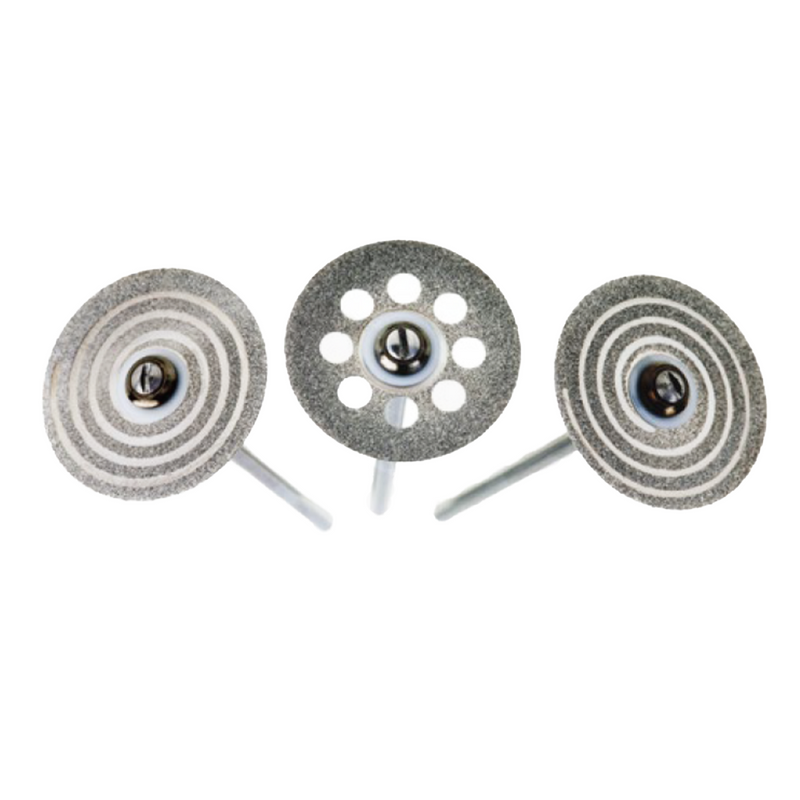

Diamond Burs

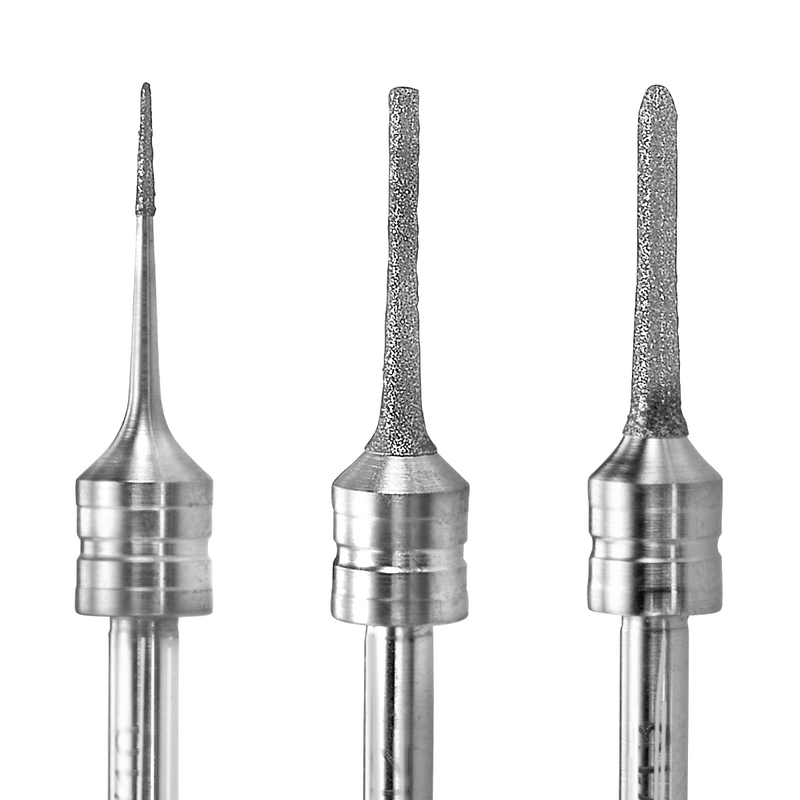

Diamond burs represent the gold standard for cutting efficiency in dental procedures. These instruments feature industrial-grade diamond particles bonded to a metal substrate, providing unmatched durability and consistent performance. Research by Siegel and von Fraunhofer demonstrated that diamond burs maintain their cutting effectiveness throughout extended clinical use, making them indispensable for precision dentistry.

The diamond particles vary in size, creating different cutting characteristics. Coarse diamond burs excel at rapid material removal, while fine and super-fine variants provide smooth finishing and polishing capabilities. This versatility makes diamond burs suitable for everything from initial cavity preparation to final restoration contouring.

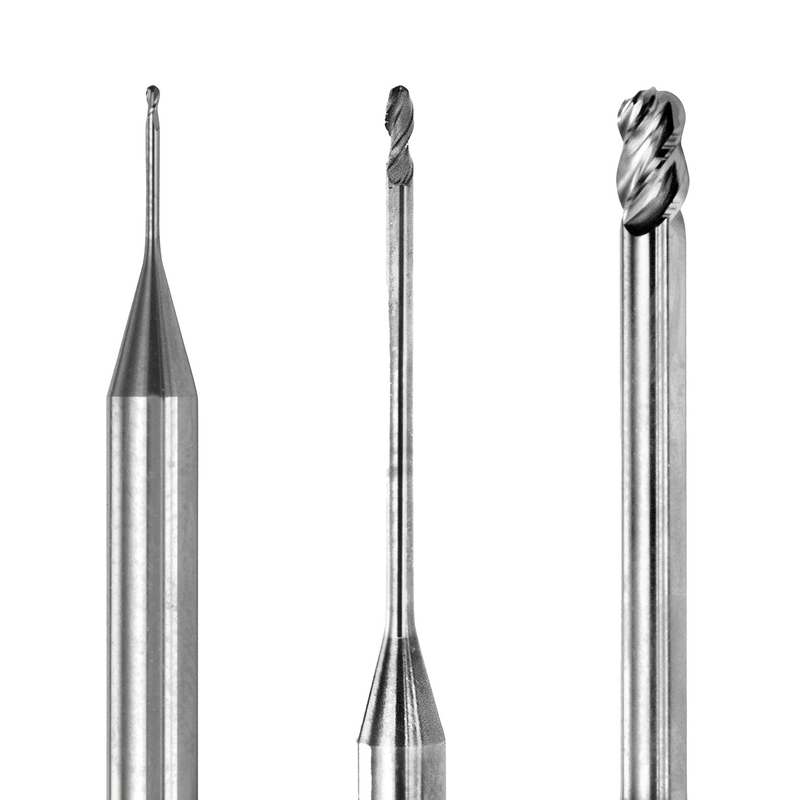

Carbide Burs

Tungsten carbide burs offer exceptional cutting performance through their unique composition of tungsten carbide particles within a cobalt matrix. Studies by Mohn et al. highlight the superior heat dissipation properties of carbide burs, which contributes to patient comfort and reduces the risk of thermal damage to dental tissues.

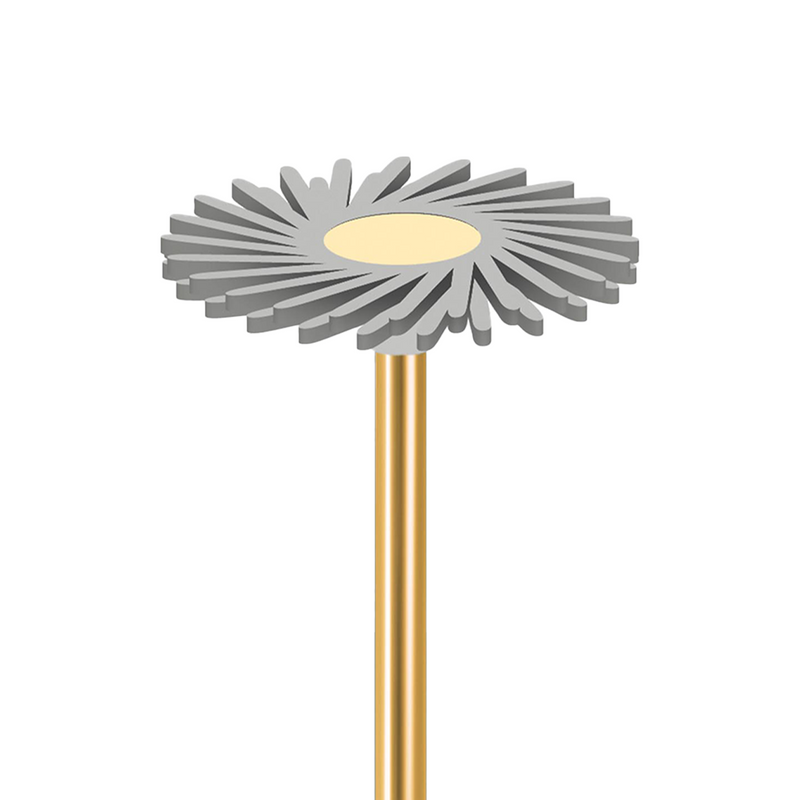

The blade design of carbide burs varies significantly, with straight flute, cross-cut, and spiral configurations each offering distinct advantages. Cross-cut carbide burs are particularly valued for their efficient debris removal and reduced clogging during procedures, while straight flute designs provide exceptional smoothness for finishing work.

Material Science and Bur Performance

The performance of dental burs is fundamentally linked to their material composition and manufacturing quality. Advanced metallurgy and surface treatments have revolutionized bur performance, with modern manufacturing techniques producing instruments that far exceed the capabilities of earlier generations.

Diamond bur technology has evolved to include various bonding methods, with electroplated and sintered diamond burs offering different performance characteristics. Electroplated diamond burs provide initial aggressive cutting with gradually decreasing efficiency, while sintered diamond burs maintain more consistent performance throughout their lifespan.

Carbide bur manufacturing involves precise control of grain size and cobalt content, directly affecting cutting efficiency and durability. Research by Ramalho et al. demonstrates how optimized carbide compositions enhance cutting performance while reducing wear rates.

Quality Standards and Manufacturing Excellence

International standards, particularly ISO 14457, establish rigorous criteria for dental bur manufacturing. These standards ensure dimensional accuracy, material consistency, and performance reliability across different manufacturers. Quality dental burs must demonstrate precise concentricity, appropriate surface finish, and consistent hardness values to meet clinical demands.

Manufacturing excellence extends beyond basic standards to include advanced quality control measures. Premium manufacturers employ sophisticated testing protocols that evaluate cutting efficiency, durability, and consistency across production batches. This attention to quality ensures that practitioners receive instruments that perform predictably in clinical situations.

Bur Selection Strategies

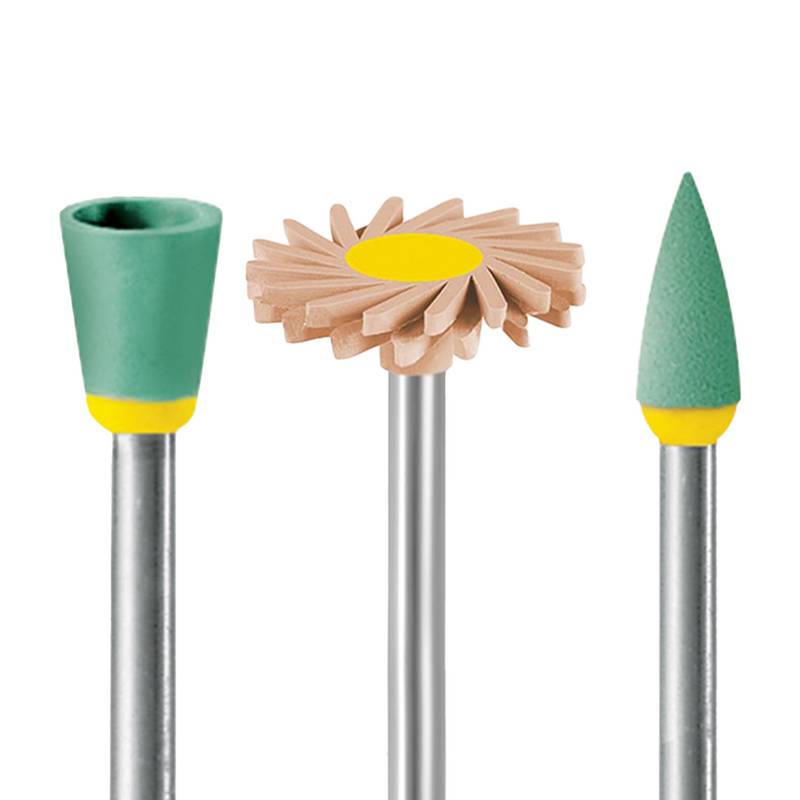

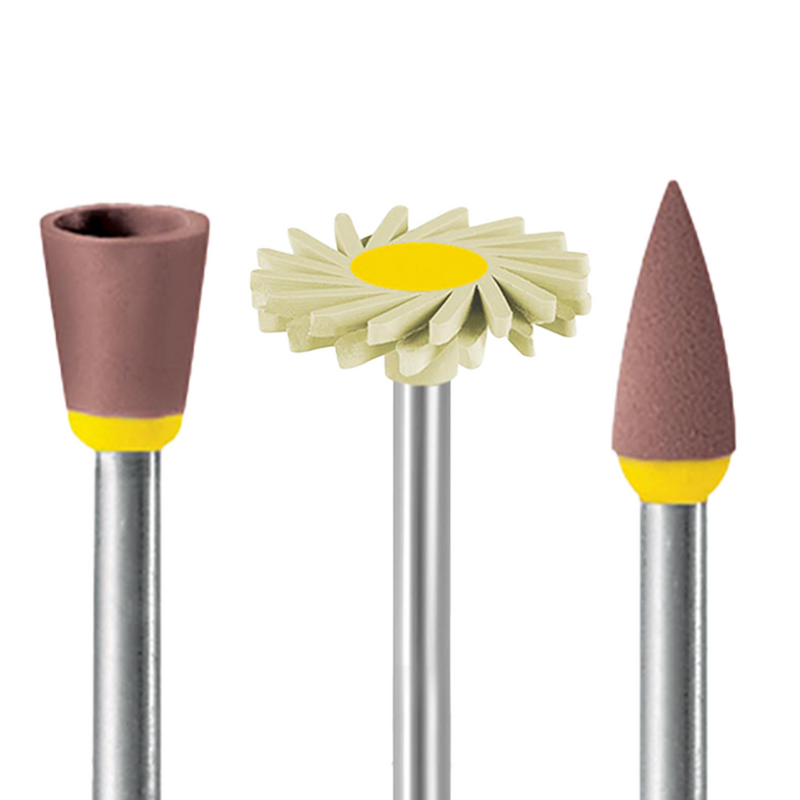

Selecting the appropriate dental bur requires understanding both the clinical requirements and the performance characteristics of different bur types. The decision process involves evaluating the material to be cut, the desired finish quality, and the specific procedural objectives.

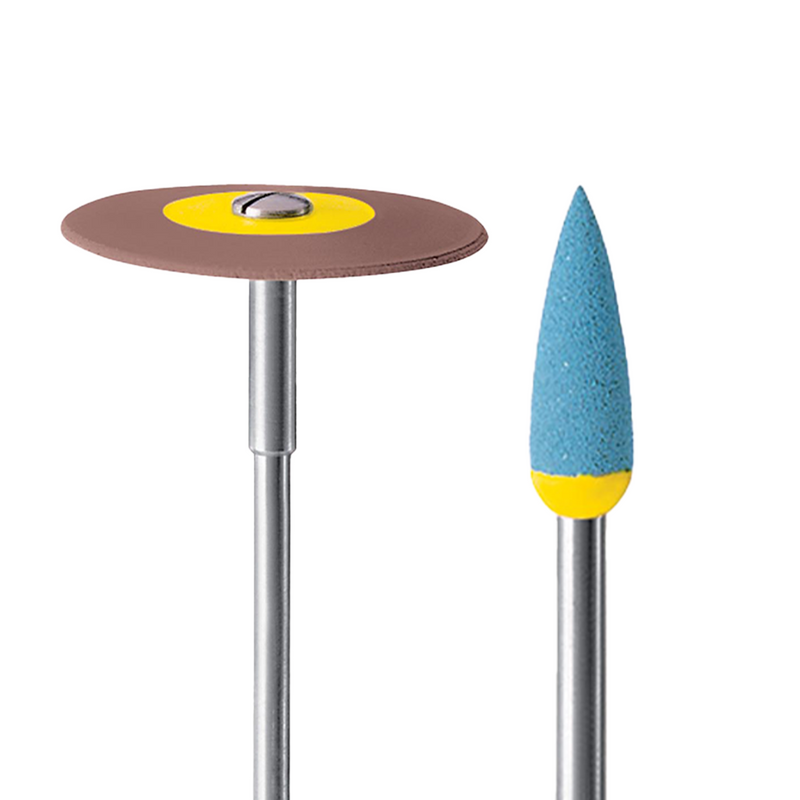

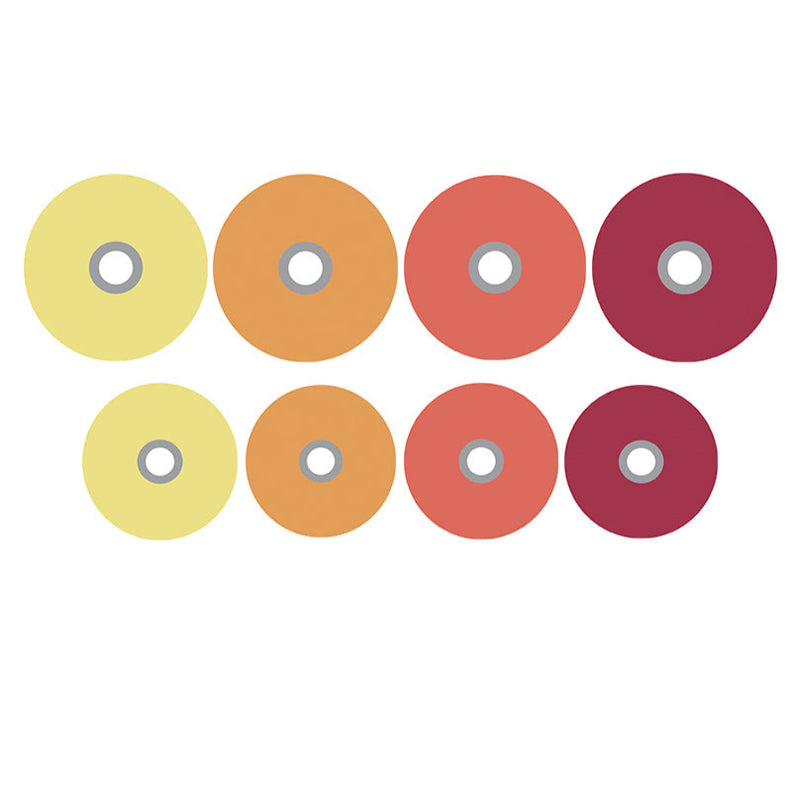

For restorative procedures, the progression from coarse to fine grits allows for efficient material removal followed by precise finishing. This systematic approach ensures optimal results while minimizing procedural time. Research supports the use of bur sequences that match the hardness and abrasiveness to the specific phase of the procedure.

Procedural efficiency benefits significantly from proper bur selection. Using burs specifically designed for particular applications reduces cutting time, improves surface quality, and enhances overall treatment outcomes. The investment in appropriate bur selection pays dividends in reduced chairside time and improved patient satisfaction.

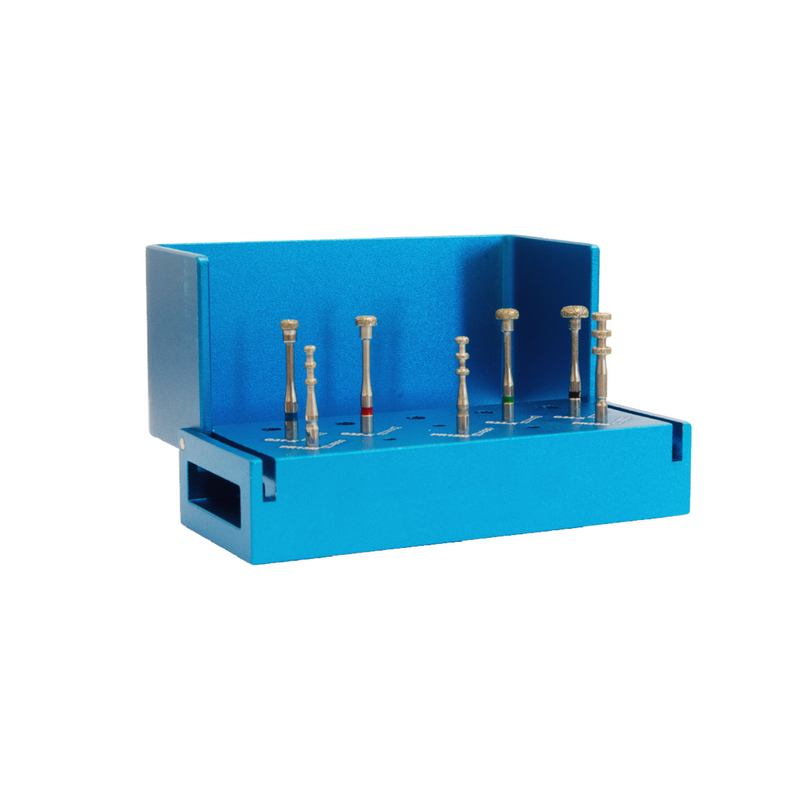

Infection Control and Sterilization

Modern dental practice demands strict adherence to infection control protocols, with dental burs requiring thorough decontamination and sterilization between uses. The porous nature of some bur surfaces and the complexity of cutting geometries present unique challenges for effective cleaning and sterilization.

Proper decontamination begins immediately after use, with thorough cleaning to remove all organic debris. Ultrasonic cleaning systems effectively remove adherent materials from complex bur geometries, preparing instruments for sterilization. Steam sterilization remains the gold standard for dental bur sterilization, with specific time and temperature parameters ensuring complete pathogen elimination.

Storage systems must maintain sterility while protecting bur integrity. Modern bur storage solutions provide individual compartments that prevent damage while maintaining organization and sterility. Proper storage extends bur lifespan while ensuring consistent performance.

Emerging Technologies and Future Developments

The dental bur industry continues to evolve with advances in materials science and manufacturing technology. Nanostructured coatings enhance cutting performance while extending bur lifespan. Research by Zhang et al. demonstrates significant improvements in cutting efficiency with laser-textured bur surfaces.

Advanced manufacturing techniques enable the production of burs with unprecedented precision and consistency. Computer-controlled grinding and quality control systems ensure that each bur meets exacting specifications, providing practitioners with instruments that perform reliably in demanding clinical situations.

Future developments promise even greater improvements in bur performance, with smart technologies potentially providing real-time feedback on cutting conditions and bur condition. These advances will further enhance procedural precision while supporting optimal clinical outcomes.

Safety Considerations and Best Practices

Safe bur usage requires understanding both the capabilities and limitations of these precision instruments. Proper handling techniques prevent instrument damage while ensuring optimal cutting performance. Regular inspection for wear and damage prevents unexpected failures that could compromise patient safety.

Training in proper bur usage techniques ensures that clinical staff can maximize instrument performance while maintaining safety standards. Understanding the relationship between bur design and cutting characteristics enables practitioners to select appropriate instruments for specific clinical situations.

Emergency procedures for bur fracture or malfunction should be established and regularly reviewed. While rare, bur failures can present serious risks that require immediate and appropriate response to ensure patient safety.

Dental Bur - Conclusion

Dental burs represent sophisticated precision instruments that enable modern dentistry to achieve exceptional clinical outcomes. Understanding the various types, applications, and selection criteria allows practitioners to optimize their instrument choices for specific clinical needs. The continued evolution of bur technology promises even greater capabilities in the future, supporting the delivery of superior dental care.

The investment in high-quality dental burs pays dividends through improved procedural efficiency, enhanced clinical outcomes, and increased patient satisfaction. By understanding the science behind these essential instruments, practitioners can make informed decisions that benefit both their practice and their patients.

References:

- Siegel, S. C., & von Fraunhofer, J. A. (2000). The effect of handpiece spray patterns on cutting efficiency. Journal of the American Dental Association, 131(7), 942-947.

-

Peters, O. A., & Barbakow, F. (2000). Effects of irrigation on debris and smear layer on canal walls prepared by two rotary techniques.

Journal of Endodontics, 28(6), 419-421.

Join Our

Newsletter!

Duties are now included in the product price

Duties are now included in the product price