Diamond Burs - Shop Premium Dental Burs Online

Dental diamond burs are essential tools in modern dentistry, providing unparalleled precision and efficiency for a range of procedures. These rotary instruments, embedded with diamond particles, are used to cut, grind, and polish hard tissues in the mouth, such as enamel and dentin. Their applications span from routine cavity preparations to complex restorative and cosmetic procedures.

Applications in Dentistry

Restorative Dentistry

In restorative dentistry, dental diamond burs are pivotal for cavity preparation, removal of old restorations, and contouring composite materials. Their precision allows for minimal tooth structure removal, preserving as much natural enamel and dentin as possible. The fine control offered by diamond burs aids in achieving optimal margins and smooth surfaces, essential for the longevity of restorations and patient comfort.

Cosmetic Dentistry

Cosmetic procedures, such as veneer preparations and crown lengthening, demand meticulous attention to detail. Dental diamond burs facilitate the delicate reduction and shaping of teeth, ensuring a natural and aesthetically pleasing outcome. Their versatility allows cosmetic dentists to refine and polish the tooth surface, enhancing the overall appearance and achieving the desired esthetic results.

Endodontics

In endodontics, diamond burs are utilized for access cavity preparation, ensuring precise and efficient entry into the pulp chamber. Their ability to cut through hard tissues with minimal pressure reduces the risk of microfractures and enhances the success rate of root canal treatments. Specialized endodontic diamond burs, with extended lengths and specific tapers, aid in navigating the complex anatomy of root canals.

Orthodontics

Orthodontists employ dental diamond burs for interproximal reduction (IPR) and enameloplasty. These procedures involve the selective removal of enamel to create space or adjust tooth contours, facilitating orthodontic movement and improving occlusal relationships. The precision and control provided by diamond burs are critical for achieving the desired outcomes without compromising tooth integrity.

Periodontics

Periodontists use diamond burs for periodontal procedures such as gingivectomy and crown lengthening. The burs allow for precise tissue removal and contouring, promoting better healing and improved periodontal health. The versatility and precision of diamond burs are essential in achieving clean, smooth edges in soft tissue management.

Oral Surgery

In oral surgery, dental diamond burs are used for procedures like bone contouring, impacted tooth removal, and osteoplasty. Their ability to efficiently cut through hard tissues such as bone and teeth makes them invaluable for surgical precision and reducing procedural time.

Prosthodontics

Prosthodontists utilize dental diamond burs for the preparation of abutments for crowns, bridges, and implant prostheses. The precise shaping and finishing capabilities of diamond burs ensure accurate fitting of prosthetic devices, leading to improved patient outcomes and prosthetic longevity.

Dental Laboratories

In dental laboratories, diamond burs are employed for the detailed finishing and polishing of dental prostheses, including crowns, bridges, and dentures. The burs provide technicians with the ability to create smooth, precise surfaces and intricate details, ensuring high-quality restorations that meet the exact specifications required for patient care.

The Bur

The manufacturing of dental diamond burs begins with the creation of the bur itself. High-quality stainless steel or tungsten carbide rods are cut into precise lengths to form the shank. The shank is then machined to the desired specifications, including any necessary features such as grooves or flutes that facilitate attachment to dental handpieces.

The Diamond Particles

Diamond particles used in dental burs are either natural or synthetic. Synthetic diamonds, produced through high-pressure, high-temperature (HPHT) processes or chemical vapor deposition (CVD), are commonly preferred for their consistency in size and shape. The diamond particles are sorted and graded according to size, ensuring uniformity and optimal cutting performance.

The Bonding Process

The diamond particles are bonded to the bur head through advanced techniques such as electroplating or sintering.

-

Electroplating: This process involves coating the bur head with a single layer of diamond grit. The bur is immersed in an electrolyte solution, and an electric current is passed through, causing the diamond particles to adhere to the bur head. Electroplated burs provide sharp and aggressive cutting edges, ideal for precision tasks.

-

Sintering: In this method, multiple layers of diamond particles are incorporated within a metal matrix. The bur head is formed by mixing diamond particles with a metal binder and then heating the mixture to bond the components. Sintered burs offer extended longevity and consistent performance, as new layers of diamond are exposed as the outer layers wear away.

Quality Assurance

Quality assurance is a critical step in the production of dental diamond burs. Each bur undergoes rigorous testing to ensure it meets strict standards for cutting efficiency, durability, and safety. This includes:

- Visual Inspection: To check for any defects or irregularities in the bur and diamond coating.

- Performance Testing: Burs are tested under simulated clinical conditions to assess cutting speed, efficiency, and wear resistance.

- Dimensional Accuracy: Precision measuring tools are used to verify the dimensions of the bur shank and head, ensuring compatibility with dental handpieces and adherence to industry standards.

- Sterilization Validation: Burs are subjected to sterilization processes to ensure they can withstand autoclaving without degradation.

By adhering to these stringent quality assurance protocols, manufacturers ensure that each dental diamond bur delivers optimal performance and reliability in clinical settings.

In conclusion, dental diamond burs are engineered with meticulous attention to detail, from the selection of high-quality materials to the advanced bonding processes that integrate diamond particles with the bur head. This comprehensive approach ensures that dental professionals can rely on these instruments for precision, efficiency, and durability across a wide range of dental procedures.

Advantages of Dental Diamond Burs

Superior Cutting Efficiency

The hardness of diamond particles ensures superior cutting efficiency, reducing the time required for procedures. This efficiency translates into shorter chair times for patients and increased productivity for dental professionals. Compared to carbide burs, diamond burs can cut through the hardest materials, including enamel and ceramic, with less effort and greater speed. This makes them particularly valuable in procedures requiring extensive reduction or precise contouring.

Enhanced Precision

The fine control offered by dental diamond burs allows for precise cutting and shaping, essential for achieving accurate margins and smooth surfaces. This precision is particularly beneficial in procedures requiring detailed work, such as veneer preparations and intricate restorations. Unlike carbide burs, which may produce chipping or rough finishes, diamond burs provide a smoother and more controlled cut, leading to superior aesthetic and functional results.

Longevity and Durability

High-quality dental diamond burs are designed to withstand the rigors of repeated use. Sintered diamond burs, in particular, offer extended lifespan due to their multi-layered construction. This durability ensures consistent performance, reducing the frequency of bur replacements and associated costs. In contrast, carbide burs, while effective for certain applications, tend to wear out faster when used on hard materials and may require more frequent replacement.

Versatility

With a wide range of shapes, sizes, and grit options, dental diamond burs are versatile tools suitable for various dental procedures. This versatility allows dentists to tailor their instrument selection to the specific requirements of each case, enhancing procedural outcomes and patient satisfaction. Diamond burs can be used for everything from gross reduction to fine polishing, whereas other burs, like steel or carbide, may be limited to specific applications.

Reduced Heat Generation

The efficient cutting action of diamond burs generates less friction and heat compared to other types of burs, minimizing the risk of thermal damage to tooth structures and surrounding tissues. This is particularly important in procedures where maintaining the integrity of the tooth is crucial, such as in endodontic access or during restorative preparations. By reducing heat generation, diamond burs help preserve the health and vitality of the tooth, contributing to better long-term outcomes for patients.

Improved Patient Comfort

The efficient and precise cutting action of diamond burs often results in less vibration and noise compared to other types of burs, enhancing patient comfort during procedures. Reduced vibration and noise contribute to a more pleasant dental experience, especially for patients with dental anxiety. Additionally, the smooth cutting action minimizes discomfort and potential trauma to the tooth and surrounding tissues, promoting quicker recovery and reduced postoperative sensitivity.

Cost-Effectiveness

Although dental diamond burs may have a higher initial cost compared to other types of burs, their durability and consistent performance result in cost savings over time. The extended lifespan and reduced need for frequent replacements make diamond burs a cost-effective choice for dental practices. By investing in high-quality diamond burs, dental professionals can achieve better results, improve patient satisfaction, and optimize their practice efficiency.

Comparison with Other Types of Dental Burs

Carbide Burs

Carbide burs are another common type of dental bur, made from tungsten carbide. They are known for their sharp cutting edges and are particularly effective for cutting through softer materials like dentin and amalgam. However, they have certain limitations compared to diamond burs:

- Cutting Efficiency: While carbide burs cut efficiently through softer materials, they are less effective on harder substances like enamel and ceramics. Diamond burs excel in these applications due to their superior hardness.

- Precision: Carbide burs can produce rougher surfaces and may lead to chipping, especially on brittle materials. Diamond burs provide a smoother finish and greater control, essential for detailed and cosmetic work.

- Durability: Carbide burs tend to wear out more quickly, especially when used on hard materials, necessitating more frequent replacements. Diamond burs, particularly sintered varieties, offer greater longevity and consistent performance.

Steel Burs

Steel burs are primarily used for polishing and finishing procedures. They are softer and less durable than carbide and diamond burs, making them suitable for less demanding applications.

- Cutting Efficiency: Steel burs are not suitable for cutting hard materials and are primarily used for polishing and finishing.

- Precision: They offer good precision for finishing work but lack the cutting power and durability of diamond and carbide burs.

- Durability: Steel burs wear out quickly and are generally considered less durable than both carbide and diamond burs.

Ceramic Burs

Ceramic burs are a newer option, often used for specific applications such as aesthetic contouring.

- Cutting Efficiency: They provide a sharp and smooth cut but are not as effective on very hard materials as diamond burs.

- Precision: Ceramic burs offer excellent precision for specific tasks but may not be as versatile as diamond burs.

- Durability: Ceramic burs are more brittle and can fracture under heavy use, whereas diamond burs offer superior durability.

Conclusion

Dental diamond burs stand out due to their superior cutting efficiency, enhanced precision, longevity, and versatility. Compared to other types of burs such as carbide, steel, and ceramic, diamond burs offer distinct advantages, especially in procedures involving hard materials and requiring fine detail work. By selecting high-quality diamond burs and using them appropriately, dental professionals can achieve better procedural outcomes, enhance patient satisfaction, and improve overall practice efficiency.

Best Practices for Use of Diamond Burs

Proper Speed and Pressure

To maximize the performance and longevity of dental diamond burs, it is essential to operate them at the recommended speeds and apply appropriate pressure. Each type of dental bur has an optimal rotational speed range, usually provided by the manufacturer. Excessive speed can cause overheating and damage both the bur and the tooth structure, while insufficient speed may lead to inefficient cutting and increased procedure time. Similarly, applying excessive pressure can cause premature wear, reduced cutting efficiency, and potential damage to the bur and tooth. Gentle, consistent pressure ensures optimal cutting performance and prolongs the lifespan of the bur.

Cooling and Lubrication

Adequate cooling and lubrication are crucial during the use of dental diamond burs to prevent overheating and potential damage to the tooth structure. Overheating can cause thermal damage to the pulp and surrounding tissues, leading to patient discomfort and compromised outcomes. The use of a water spray or air-water coolant helps maintain optimal temperature, reduce friction, and remove debris from the cutting surface. This cooling effect not only protects the tooth and surrounding tissues but also extends the life of the bur by reducing wear.

Sterilization and Maintenance

Proper sterilization and maintenance of dental diamond burs are vital to prevent cross-contamination and ensure their longevity. Autoclaving is the preferred method of sterilization for most dental burs, as it effectively eliminates bacteria, viruses, and spores. However, it is essential to follow the manufacturer's guidelines regarding sterilization cycles and temperatures to avoid damaging the burs. After each use, burs should be thoroughly cleaned to remove debris and organic matter before sterilization. This involves using a bur brush or ultrasonic cleaner to ensure all particles are removed. Regular inspection of burs is also necessary; any burs that are worn, damaged, or clogged with debris should be replaced promptly to maintain cutting efficiency and safety.

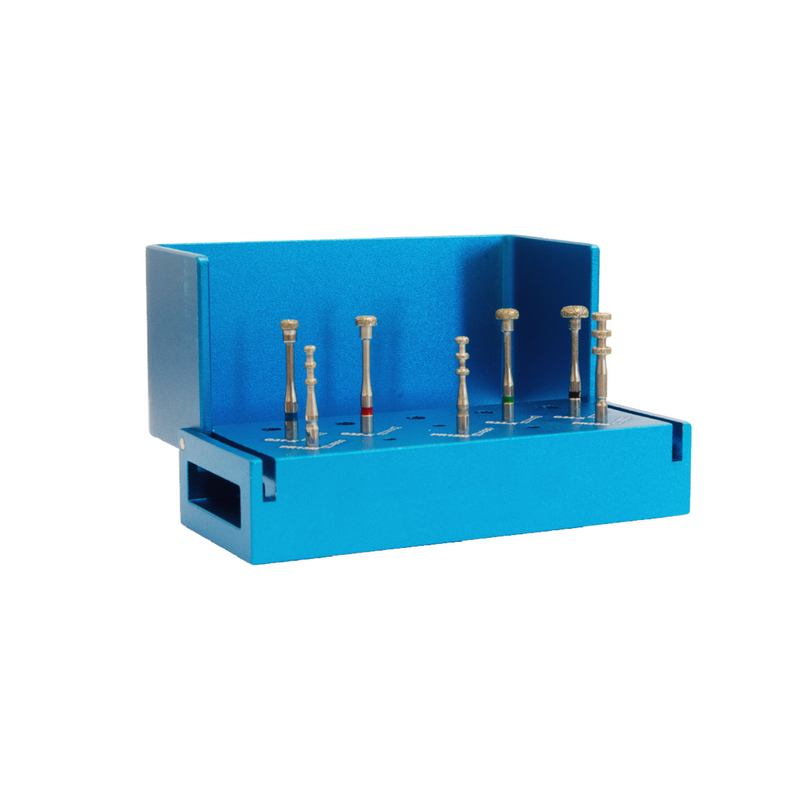

Storage and Handling

Proper storage and handling of dental diamond burs are essential to maintain their performance and prevent damage. Burs should be stored in a clean, dry environment, preferably in a designated bur block or holder that protects them from physical damage and contamination. Handling burs with care, avoiding dropping or knocking them against hard surfaces, is crucial to prevent chipping or bending. Additionally, ensuring that burs are not over-tightened in the handpiece can prevent damage to the shank and ensure smooth operation.

Selection and Usage

Selecting the appropriate bur for each specific procedure is crucial for achieving the best outcomes. Dentists should have a variety of diamond burs in different shapes, sizes, and grits to choose from, depending on the task at hand. For instance, using a coarse-grit bur for rapid material removal and a fine-grit bur for smoothing and finishing helps optimize both efficiency and results. Dentists should also be aware of the specific applications for different head designs to ensure they are using the most effective tool for each procedure.

Training and Technique

Proper training and technique are essential for the effective use of dental diamond burs. Dental professionals should be trained in the correct usage, including the optimal speeds, pressure, and cooling methods for different types of burs. Regular continuing education and hands-on training can help dentists stay updated on the latest techniques and best practices. Additionally, understanding the anatomy of the tooth and surrounding structures, as well as the specific requirements of each procedure, allows for more precise and efficient use of diamond burs.

Quality Control

Maintaining high standards of quality control in the use of dental diamond burs is essential for ensuring patient safety and achieving optimal clinical outcomes. This involves regularly reviewing and updating protocols for bur usage, sterilization, and maintenance. Keeping accurate records of bur usage and replacement can help identify patterns and improve overall practice efficiency. Dentists should also stay informed about advancements in bur technology and materials to continuously enhance their practice.

By adhering to these best practices, dental professionals can ensure the effective and safe use of dental diamond burs, ultimately enhancing procedural efficiency, patient satisfaction, and clinical outcomes.

Eagle Dental Diamond Burs: Unleashing Precision and Quality

Superior Craftsmanship

Eagle Dental Burs takes pride in delivering exceptional diamond burs that meet the stringent demands of dental professionals. Our premium diamond burs, manufactured in Israel, are engineered for optimum cutting efficiency, durability, and clinical performance.

Precision and Efficiency

Our burs feature high-accuracy cutting surfaces, allowing for swift and precise removal of dental tissues and restorative materials. The advanced design and superior diamond grit quality ensure that you can achieve increased efficiency, reduced chair time, and remarkable clinical outcomes with every use.

Why Choose Eagle Dental Burs?

At Eagle Dental Burs, we are dedicated to providing dental professionals with the highest quality diamond burs that deliver precision, reliability, and exceptional performance. Our extensive collection of industry-leading diamond burs is meticulously crafted to meet the demanding needs of dental procedures such as tooth preparation, adjusting restorations, and polishing surfaces.

Rigorous Quality Control

Each bur undergoes rigorous quality checks to ensure superior cutting precision and durability, allowing you to achieve optimal results with confidence. Our commitment to quality ensures that you receive burs that consistently perform at the highest level.

Personalized Service

What sets us apart is not only the quality of our diamond burs but also our commitment to personalized service. Our experienced team is here to assist you in selecting the right burs for your specific applications, offering expert guidance and support to ensure your complete satisfaction. We take pride in delivering not only exceptional products but also exceptional customer care.

Unmatched Clinical Performance

Experience the difference that precision and reliability can make in your dental practice. Eagle Dental Diamond Burs are designed to handle the most challenging procedures with ease, providing you with the tools you need to achieve excellent clinical outcomes and enhance patient satisfaction.

Dental Diamond Burs: Where to Buy?

When it comes to purchasing dental diamond burs, you have several options available:

Dental Supply Stores: These stores offer convenience and a wide selection of dental diamond burs from various manufacturers. They are a good choice when you need burs quickly.

Agents: If you require a large quantity or a specific type of dental diamond bur, agents can provide access to a broader range of options than dental supply stores.

Online Retailers: Online retailers offer convenience, competitive pricing, and a wide selection of dental diamond burs. You can compare prices, read customer reviews, and take advantage of discounts and free shipping.

Advantages of Buying Dental Diamond Burs Online:

- Convenience: Shop from the comfort of your own home, at any time.

- Competitive Pricing: Online retailers often offer cost-effective options.

- Easy Comparison: Compare prices and features of different dental diamond burs easily.

- Customer Service: Many online retailers provide excellent customer service, including 24/7 support and hassle-free returns.

Disadvantages of Buying Dental Diamond Burs Online:

- Inability to Physically Examine the Burs Before Purchase: This can be mitigated by choosing reputable suppliers with good return policies.

- Potential Longer Delivery Times: Plan ahead to avoid delays in your practice.

- Risks of Fraud or Counterfeit Products: Minimize risk by buying from well-reviewed and established suppliers.

How to Choose Dental Diamond Burs Manufacturers?

Choosing the right dental burs supplier online requires careful consideration of several factors:

Reputation: Research the supplier's reputation, looking for well-established companies with positive customer feedback. A good reputation often indicates reliable products and services.

Website and Social Media Presence: A professional website and active social media profiles indicate a reputable supplier. They reflect the company's commitment to transparency and customer engagement.

Good Reviews: Check reviews on platforms like Google, Facebook, Trustpilot, or Yotpo for customer satisfaction and reliability. Consistently positive reviews are a good indicator of product quality and customer service.

Communication and Knowledge: Reach out to the supplier to assess their responsiveness, professionalism, and product knowledge. A knowledgeable supplier can provide valuable guidance and support.

Wide Variation: A diverse range of products indicates a serious and established supplier. A wide selection allows you to choose the most suitable burs for your specific needs.

Start Small: Test the supplier's product quality and service before making larger purchases. This approach allows you to evaluate the supplier's reliability and the performance of their products without significant investment.

Conclusion

Online retailers offer convenience and a wide selection when buying dental diamond burs. However, it's important to consider reputation, start with a small order, evaluate the website and social media presence, check for good reviews, communicate with the supplier, and look for a wide variation of products. By doing so, you can make an informed decision and minimize potential risks associated with online shopping. Choose Eagle Dental Burs for precision, reliability, and exceptional clinical performance, and experience the difference in your dental practice.

Join Our

Newsletter!

Duties are now included in the product price

Duties are now included in the product price