0 comments

Dental Rotary Instruments: A Comprehensive Guide

Introduction

In modern dentistry, rotary instruments (commonly known as burs) are indispensable for precise, efficient, and predictable procedures. From cavity preparation to implant osteotomy, these seemingly simple devices define the precision, speed, and quality of clinical outcomes. As Eliades et al. (2021, Journal of Dentistry) observed, “Even minor variations in bur composition, grit, and wear pattern can substantially affect cutting efficiency and restorative interface quality.”

Given the extensive range of bur designs, understanding the material science, geometry, and clinical principles governing their performance is essential. This comprehensive guide integrates scientific insights, recent developments, and clinical applications to help dental professionals make informed choices and refine their procedural outcomes.

Historical Perspective

The development of dental rotary instruments mirrors the evolution of modern dentistry itself. Early hand-driven steel tools evolved into mechanical engines by the mid-19th century, marking the birth of true rotary instrumentation. The introduction of tungsten carbide burs in the 1940s and industrial diamond coating technologies in the 1960s represented major breakthroughs in cutting precision and durability.

According to Rosenstiel & Land (2020, Contemporary Fixed Prosthodontics), “The shift from manually operated steel instruments to high-speed air-turbine-driven diamond and carbide burs has transformed every aspect of restorative dentistry.” Today’s burs feature advanced microstructured coatings and laser-produced geometries designed for superior control and longevity.

Bur Types and Characteristics

Dental burs come in a variety of shapes and sizes, each designed for specific clinical applications. Understanding these differences is crucial for dental professionals.

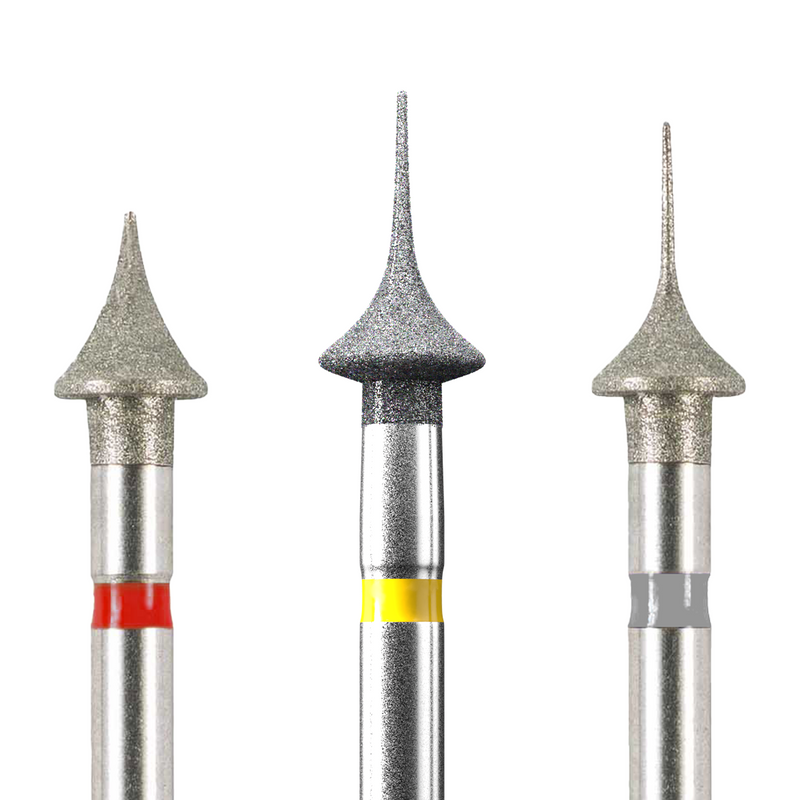

Diamond Burs:

Diamond burs remain indispensable for enamel and ceramic adjustments. Their microdiamond grit, bonded by nickel or resin matrices, ensures enhanced abrasion resistance. Coarse grits enable rapid cutting, while fine and superfine grits provide smooth surface finishes—ideal for final marginal refinement and polishing (Miyazaki et al., 2022, Dental Materials Journal).

Carbide Burs: Carbide burs, manufactured through precision sintering of tungsten carbide and cobalt, excel in cavity and crown preparation. Studies confirm their superior resistance to deformation and heat generation compared to stainless steel (da Silva et al., 2020, Journal of Prosthetic Dentistry). The fluted cutting edges offer efficient material removal with minimal vibration and heat.

Ceramic & Zirconia-Coated Burs:

Recent trends highlight the rise of ceramic burs with zirconia or silicon nitride compositions, offering lower friction and non-corrosive surfaces.

Lee et al. (2023, International Journal of Prosthodontics) reported that zirconia-coated burs produced less microcracking in ceramic restorations, suggesting improved safety for brittle materials.

Specialty Burs: These include endodontic burs for root canal treatments, surgical burs for implant procedures, and crown preparation burs, each designed for specific clinical applications. Specialty burs often feature unique shapes and coatings tailored to their respective uses.

Bur Head Shapes: Shapes such as round, pear, cylinder, and tapered play a crucial role in determining a bur's application and accessibility. Advancements in bur coatings, like diamond-coated and zirconia-coated burs, offer enhanced cutting performance and longevity, making them valuable investments for dental practices.

Cutting Efficiency & Surface Finish

Cutting efficiency depends on bur grit, geometry, applied pressure, and rotational speed. Optimizing these parameters minimizes heat and enhances restorative interface quality.

Pereira et al. (2022, Clinical Oral Investigations) demonstrated that high-speed diamond burs (>200,000 rpm) coupled with water spray cooling maintained pulp temperature below the 5.5°C safety threshold defined by Zach & Cohen.

Techniques for Optimization: Proper bur selection, appropriate speed and pressure, and effective coolant usage can significantly improve cutting efficiency. Strategically combining different bur types and grit sizes helps achieve smooth, textured, or polished surfaces tailored to specific procedures and desired outcomes.

Specialized Burs & Applications

Certain dental procedures demand specialized bur designs and applications:

Endodontic Burs: These burs are indispensable for root canal treatments, allowing precise preparation and shaping of root canals with their unique shapes and coatings.

Surgical Burs: Designed for implant procedures, surgical burs facilitate accurate osteotomy site preparation and bone contouring.

Crown and Bridge Work Burs: These specialized burs play a crucial role in achieving precise marginal fit and occlusal anatomy.

Innovative Designs: Burs used in minimally invasive dentistry enable conservative tooth preparations and minimized tissue trauma, enhancing patient comfort and treatment outcomes.

Advanced Materials

Modern burs are manufactured from advanced alloys and composite materials that enhance durability and biocompatibility:

-

Tungsten carbide: High hardness, low wear.

-

Nickel-titanium (NiTi): Flexible and fracture-resistant—ideal for endodontic shaping.

-

Polycrystalline diamond (PCD): Provides superior edge retention for cutting ceramics and zirconia.

Borges et al. (2021, Journal of Applied Oral Science) observed that hybrid burs combining diamond nanoparticles with carbide matrices achieved up to 40% longer service life while maintaining cutting precision.

Maintenance & Care

Proper maintenance ensures both performance consistency and infection control compliance.

-

Cleaning: Ultrasonic pre-cleaning followed by autoclaving prolongs lifespan and prevents biofilm formation (Centers for Disease Control and Prevention, 2022 Guidelines).

-

Inspection: Replace burs showing visible wear, corrosion, or dull edges, as these reduce cutting efficiency and increase patient discomfort.

-

Storage: Use bur blocks or sterilization cassettes to prevent mechanical damage and maintain organization.

Choi et al. (2021, Infection Control in Dentistry) highlighted that worn burs can harbor up to 10⁵ bacterial CFUs, underscoring the necessity of strict instrument sanitation protocols.

Clinical Implications

Selecting the right bur influences every clinical outcome—from marginal fit and surface smoothness to postoperative sensitivity. Advances such as computer-aided milling-compatible burs and minimally invasive micro-grit designs have streamlined digital workflows and chairside adjustments.

As Jepsen & Frencken (2022, International Dental Journal) emphasize, “The operator’s understanding of bur behavior, coupled with evidence-based selection, defines procedural efficiency and patient comfort.”

Conclusions

Mastery of dental rotary instruments blends material science, precision engineering, and clinical judgment. New developments in hybrid materials, surface coatings, and ergonomic handpiece integration continue to raise the standard for restorative and surgical procedures.

Staying current with the scientific literature, inspecting burs regularly, and matching instrument design to procedure type empower clinicians to achieve better durability, precision, and patient outcomes with every rotation.

References

-

Eliades, G. et al. (2021). Microstructural and functional performance of diamond rotary instruments in restorative dentistry. Journal of Dentistry, 112, 103728.

-

Rosenstiel, S. F., & Land, M. F. (2020). Contemporary Fixed Prosthodontics. Elsevier.

-

Miyazaki, T. et al. (2022). Performance and wear behavior of diamond burs on enamel and ceramics. Dental Materials Journal, 41(8), 1264–1271.

-

da Silva, M. R. et al. (2020). Cutting efficiency and durability of different carbide burs in restorative dentistry. Journal of Prosthetic Dentistry, 124(3), 345–352.

-

Lee, S.-H. et al. (2023). Zirconia-coated burs for ceramic restorations: A comparative microdamage analysis. International Journal of Prosthodontics, 36(2), 145–152.

-

Pereira, L. H. et al. (2022). Thermal effects of different rotary parameters during tooth preparation. Clinical Oral Investigations, 26(5), 3781–3790.

-

Borges, A. L. et al. (2021). Hybrid diamond-carbide burs: Mechanical properties and clinical lifespan. Journal of Applied Oral Science, 29, e20210216.

-

Centers for Disease Control and Prevention (CDC). (2022). Guidelines for Infection Control in Dental Health-Care Settings.

-

Choi, Y.-J. et al. (2021). Bacterial contamination and sterilization efficacy of reused dental burs. Infection Control in Dentistry, 13(4), 241–248.

-

Jepsen, S. & Frencken, J. (2022). Evidence-based selection and behavior of rotary instruments in clinical dentistry. International Dental Journal, 72(3), 287–297.

Duties are now included in the product price

Duties are now included in the product price

0 comments