0 comments

Dental Burs Evolution: From Ancient Tools to Modern Marvels

The history of dental burs is a fascinating journey, tracing back to ancient civilizations where early practitioners used rudimentary tools made from bone, flint, or copper. Fast forward to today, and dental burs have transformed into precision-engineered instruments crucial for modern dentistry.

Advancements in Manufacturing

The manufacturing of dental burs has undergone remarkable advancements. During the industrial revolution, the shift to mass production marked a significant turning point. Key developments include the introduction of tungsten carbide and diamond-coated burs, which revolutionized dental procedures.

-

Tungsten Carbide Burs: Renowned for their durability, these burs are crafted from a mix of tungsten powder and carbon. The manufacturing process involves molding, sintering at high temperatures, and shaping, making them a staple in dental procedures for their strength and efficiency.

-

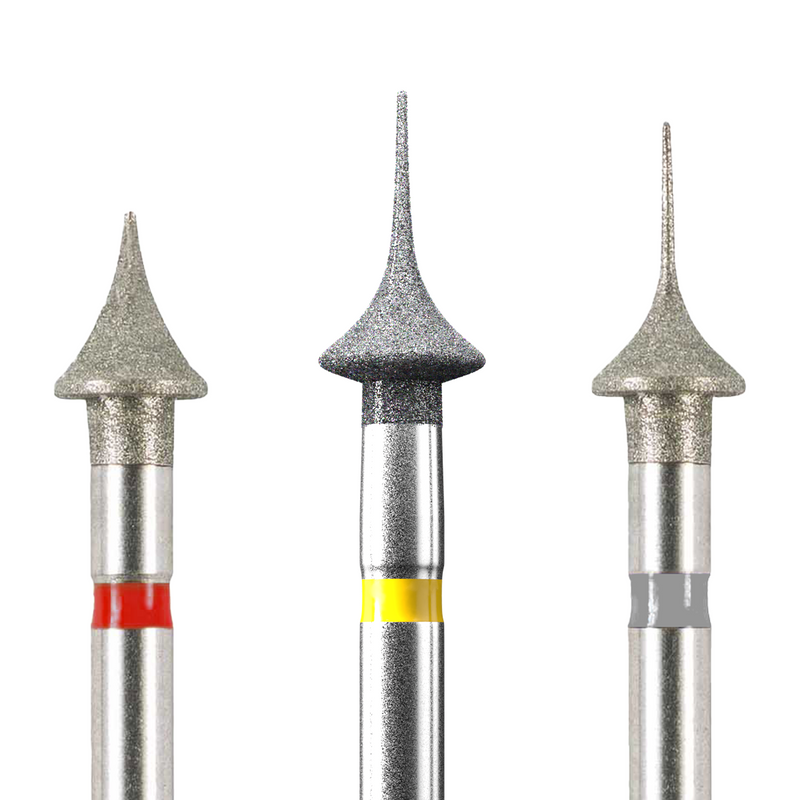

Diamond-Coated Burs: Starting with a tungsten carbide base, these burs have a layer of industrial diamonds applied through electroplating or brazing. The diamond coating enhances their cutting capabilities, making them essential for precise and efficient work.

Modern Applications and Types

In today’s dental practice, various types of burs are used for different applications:

- Dental Burs Carbide: These are ideal for routine procedures due to their robustness and longevity.

- Dental Burs Diamond: Perfect for intricate tasks, these burs offer superior cutting precision.

- Dental Burs Surgical: Designed for surgical procedures, these burs provide accuracy and control.

- Dental Burs Lab: Used in dental labs, these burs are crucial for crafting and adjusting dental prosthetics.

- Dental Burs Polishers: These burs are essential for finishing and polishing dental surfaces to a high standard.

- Dental Burs Gold: A premium option, gold burs are prized for their durability and smooth cutting action.

- Dental Burs Milling: Special burs made for grinding and cutting in milling units.

The Future of Dental Burs

Looking ahead, the innovation in dental burs continues with advances in materials and technology. Emerging trends include the development of smart burs with integrated sensors and adaptive coatings that promise even greater precision and efficiency. These advancements aim to further enhance dental procedures and improve patient outcomes.

Conclusion

The evolution of dental burs—from ancient, crude tools to today’s high-performance carbide and diamond-coated instruments—reflects significant progress in dental technology. As we continue to innovate, the precision and versatility of dental burs will enhance both patient care and practitioner capabilities. The journey of dental burs underscores a commitment to advancing dental care and achieving perfect smiles for future generations.

Duties are now included in the product price

Duties are now included in the product price

0 comments