0 comments

Introduction

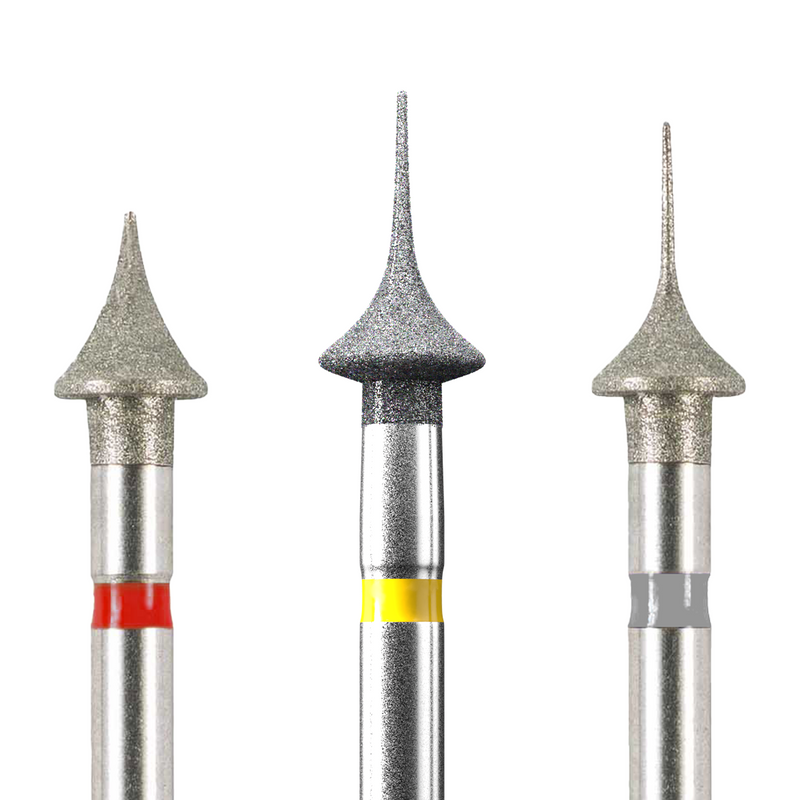

Diamond burs are essential rotary instruments in restorative and prosthetic dentistry. Their cutting efficiency impacts every step of a procedure - from preparation time to thermal safety and precision.

Repeated use and sterilization affect bur performance. So, how many clinical uses can a diamond bur withstand before it becomes inefficient?

This article provides an evidence-based answer, summarizing findings from a 2023 comparative study and other recent literature.

What Is Cutting Efficiency?

Cutting efficiency refers to how well a bur removes tooth or ceramic material with minimal force and time. It is influenced by:

-

Grit size: Coarse burs cut faster but leave rougher surfaces. Fine burs provide smoother finishes but dull more quickly.

-

Applied pressure: Too much pressure accelerates wear and increases heat.

-

Rotational speed: Higher speeds may improve cutting but also wear burs faster.

-

Bur material and bonding: Electroplated burs wear faster than sintered or brazed burs.

Clinically, reduced cutting efficiency is indicated by prolonged preparation times, increased heat generation, debris accumulation, and visible surface polishing or blunting of the bur.

Wear and Sterilization

Diamond burs degrade via two principal mechanisms:

-

Mechanical wear: Progressive loss of diamond particles and matrix erosion due to repeated contact with hard substrates

-

Thermal/chemical degradation: Repeated autoclave cycles exacerbate matrix breakdown and diamond loss, even if the bur appears macroscopically intact

Recent evidence confirms that five or more sterilization cycles significantly reduce cutting efficiency, with electroplated burs being particularly susceptible. Most manufacturers and independent studies now recommend limiting the number of uses and sterilizations per bur.

2023 In-Vitro Study Highlights

A pivotal 2023 in-vitro study by Borzangy et al. compared diamond, tungsten-carbide, and ceramic burs for sectioning monolithic zirconia and lithium disilicate crowns. Key findings include:

-

Diamond burs demonstrated the highest initial cutting efficiency, particularly on zirconia.

-

Cutting time increased significantly after each use; by the third cycle, efficiency dropped markedly.

-

SEM imaging revealed diamond particle loss after just one use, with EDS confirming matrix degradation and increased exposure of the metal binder.

-

While the efficiency decline is statistically significant, the clinical impact (e.g., a 61-second difference between the first and third uses) may be modest for single procedures but accumulates during high-volume or complex cases

How Diamond Burs Perform on Different Materials

Zirconia:

Diamond burs excel in cutting zirconia but exhibit rapid wear due to the material’s extreme hardness. The 2023 study recommends a maximum of two uses per bur for zirconia, unless a specialized zirconia bur is employed.

Lithium Disilicate:

Diamond burs maintain efficiency slightly longer on lithium disilicate, with acceptable performance across two to three uses.

Comparison with Other Burs:

-

Carbide burs: Offer steady, reliable performance but are less effective for hard ceramics.

-

Ceramic burs: Provide conservative, minimally invasive cutting but are slower and best reserved for select scenarios.

Clinical Guidelines for Bur Replacement

Based on current evidence:

-

Replace diamond burs after 2–3 clinical uses, especially when sectioning ceramics such as zirconia or lithium disilicate.

-

Limit each bur to a maximum of five sterilization cycles to avoid substantial efficiency loss.

-

Inspect burs prior to each use: Discard any bur exhibiting surface polishing, clogging, or visible wear.

-

Implement usage tracking: Use color-coded trays or digital logs to monitor bur age and usage frequency, optimizing both safety and cost-effectiveness.

Optimize Your Workflow

Persisting with a dull bur can result in:

-

Prolonged chair time and increased operator fatigue

-

Elevated intraoperative temperatures, risking pulpal and tissue injury

-

Inconsistent margins, potentially compromising restoration longevity

Proactive replacement of diamond burs ensures:

Summary

Diamond burs deliver superior cutting performance, particularly for hard ceramic materials. However, to maintain optimal clinical results and minimize procedural risks, they should be retired after 2–3 uses or five sterilization cycles. Adopting evidence-based replacement protocols and robust inventory management will improve efficiency, safety, and long-term restorative success in dental practice.

References

-

Public Health Ontario. Effect of Cleaning and Sterilization Processes on the Cutting Efficiency of Dental Burs. 2023. PDF

-

Borzangy S. et al. (2024). Cutting efficiency of different dental diamond rotary instrument types for sectioning monolithic zirconia and lithium disilicate anatomical crowns. J Stomatol Dent Res. PMC

-

DentalTrey. Bur Selection and Considerations to Improve Patient Care. 2020. PDF

-

Indian J Dent Res. (2019). Cutting efficiency of different diamond burs after repeated cuts and sterilization cycles in autoclave. PubMed

-

Siegel SC et al. (2016). Comparison of cutting efficiency with different diamond burs and water coolant flow. ScienceDirect

-

Rosentritt M et al. (2024). Cutting Efficiency of Diamond Grinders on Composite and Zirconia. MDPI

-

van Aswegen A et al. (2022). A comparative study of the cutting efficiency of diamond burs on zirconia. University of Pretoria Repository

Duties are now included in the product price

Duties are now included in the product price

0 comments