What are zirconia milling burs?

Zirconia milling burs are rotary instruments specifically designed for milling zirconia blocks and other abrasive materials. They are used in dental milling units to precisely shape and contour zirconia restorations for dental prosthetics.

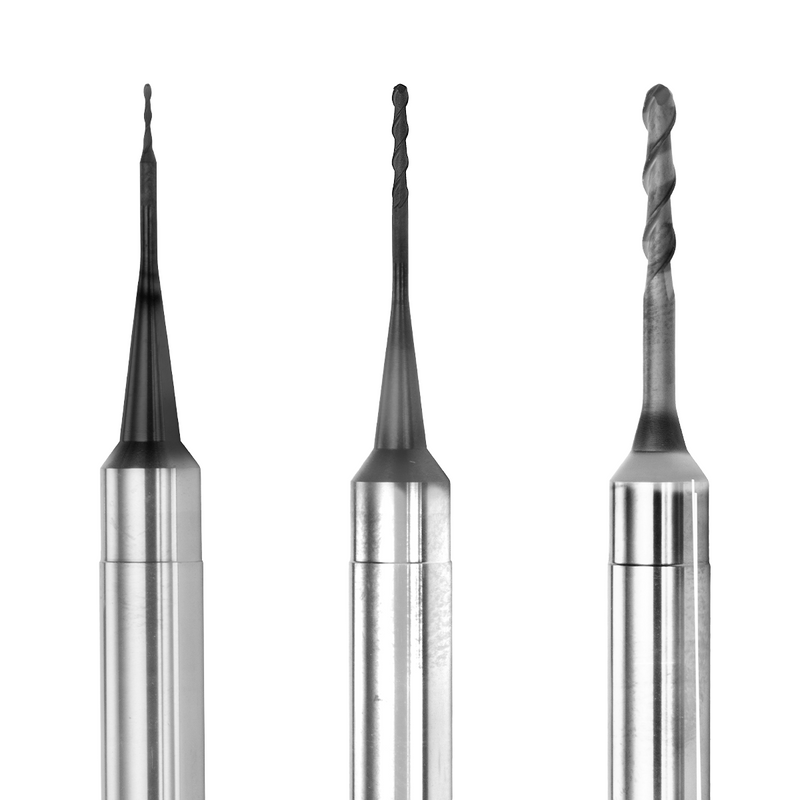

Types of Zirconia Milling Burs

There are various types of zirconia milling burs available, including different shapes, sizes, and coatings. Some common variations include cylindrical, tapered, and ball-shaped burs, each serving specific milling purposes and accommodating different milling unit configurations.

The most popular types of burs to mill zirconia are uncoated milling burs, DLC coated milling burs, and CVD diamond coated milling burs.

Uncoated Milling Burs

Uncoated milling burs are the most basic type of zirconia milling burs. They are made from a variety of materials, including tungsten carbide and steel. They are typically less expensive than coated burs, but they also have a shorter lifespan.

DLC Coated Milling Burs

DLC coated milling burs are a step up from uncoated burs. They are made from a material called diamond-like carbon, which is very hard and durable. DLC coated burs offer a longer lifespan than uncoated burs, but they are also more expensive.

CVD Diamond Coated Milling Burs

CVD diamond coated milling burs are the most advanced type of zirconia milling burs. They are made with a process called chemical vapor deposition, which bonds a thin layer of diamond particles to the cutting edge. This creates a very strong and durable coating that can withstand the high temperatures and pressures generated during milling. CVD diamond coated burs offer the longest lifespan of all types of zirconia milling burs, but they are also the most expensive.

What is a CVD diamond coating?

A CVD diamond coating is a thin layer of diamond particles that is bonded to the cutting edge of a milling bur. CVD stands for chemical vapor deposition, and it is the process that is used to create the coating. The diamond particles are deposited onto the cutting edge in a vacuum, and they are then bonded to the surface using heat and pressure.

Benefits of CVD Diamond Coated Milling Burs

CVD diamond coated milling burs offer a number of benefits over other types of zirconia milling burs. These benefits include:

- Longer lifespan

- Increased cutting efficiency

- Improved heat dissipation

- Reduced wear

- Smoother finish

Eagle Dental Zirconia Milling Burs

Eagle Dental zirconia milling burs are made in Israel and feature consistent quality, high compatibility, and durability. Our zirconia milling burs are CVD coated for longer shelf life and higher efficiency when cutting or milling zirconia and other abrasive materials.

Eagle Dental zirconia milling burs are available for the following CAD CAM milling units:

Sirona Cerec: MCX5

ZirkonZahn: M1, M2, M4, M5 , M6

Roland: DWX-30, DWX-50, DWX-42W, DWX-51D, DWX-52D, DWX-52DC

Ammann Girbach: Ceramill Mikro 4x, 5x, Micro IC, Motion2 5x

Join Our

Newsletter!

Duties are now included in the product price

Duties are now included in the product price